Why is soil contamination of grass silage an issue?

Soil is a source of enterobacteria and clostridia, which increase the risk of a poor fermentation. Wilt to at least 30% dry matter and use a silage additive to increase the rate of fermentation.

Soil is also a source of listeria, which is associated with drier silages and haylage where the pH does not fall low enough to inhibit it, and which brings animal health risks. If there is a risk of listeria, using a suitable additive to reduce the pH low enough is especially important.

If silage has an ash content above 10% dry matter it is a good indicator of soil contamination.

How to minimise soil contamination of grass silage?

- Fix muddy gateways

- Trap moles and roll fields before mowing

- Avoid handling the grass in wet weather

- Increase cutting height

- Avoid running machinery over the cut grass

- Ensure tedders and rakes are set high enough

- Clean clamp machinery, especially wheels, before starting silage-making

- Keep the clamp apron clean and don’t allow field machinery and clamp machinery to run over the same area

How much effluent does grass silage produce?

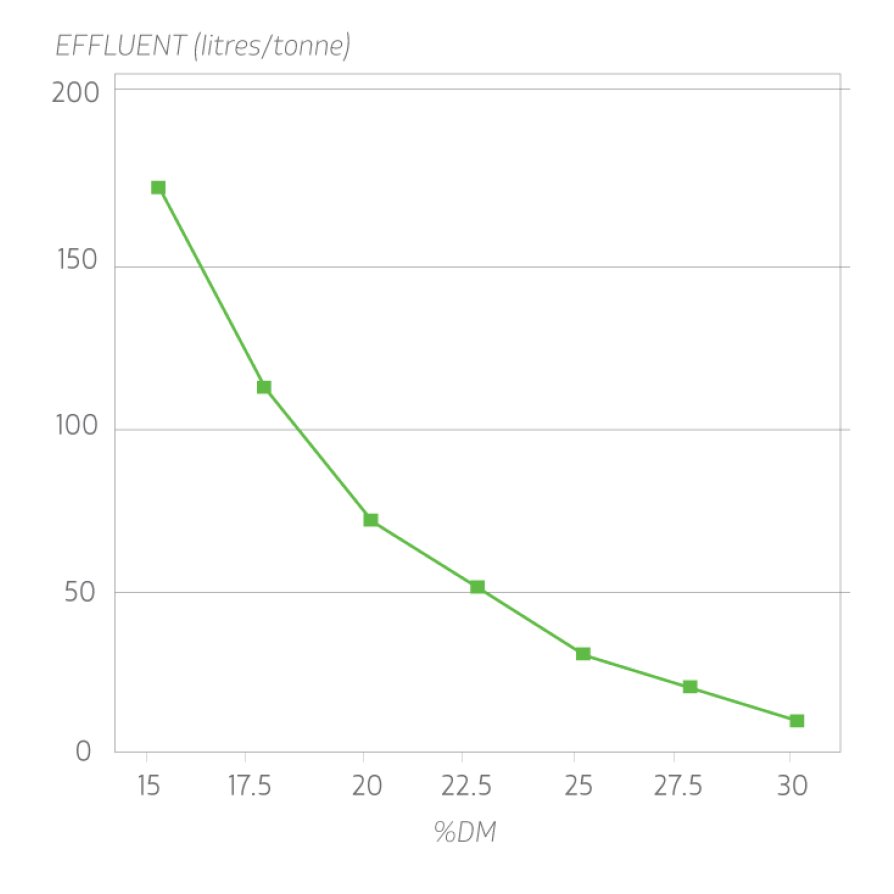

The amount of effluent produced is dependent mainly on the % dry matter of the crop and ensiling. If grass is ensiled above 25% dry matter, effluent production will be negligible.

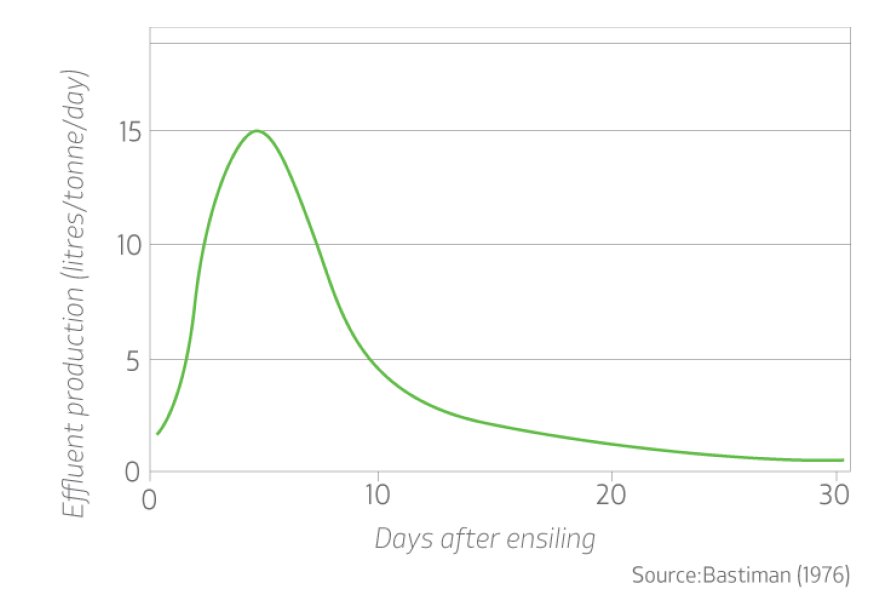

Effluent production is very uneven; about 50% of the total being produced in the first week. The maximum daily effluent production is about 10% of the total produced.

What factors affect grass silage effluent production?

- Percentage dry matter or stage of growth of the crop

- Rain/heavy dew on the crop

- Chop length – more cut ends release more effluent

- Acid additives can cause increased effluent

- Enzyme additives have been associated with increased effluent

- Heavy rolling squeezes effluent from wet crops

- High clamps increase hydraulic pressure – also squeezing out effluent

- Aerobic activity in the clamp produces water

- Poorer fermentations result in greater DM losses, creating a wetter silage

Why is reducing grass silage effluent so important?

- Silage effluent is the most corrosive effluent produced on farm and the most polluting (being 200 times worse than raw sewage)

- Silage effluent represents a loss of readily-available nutrients – typically it has a dry matter (DM) content of 6%, a metabolisable energy content of 12.5 MJ/kgDM, and a crude protein content of about 19% DM

- The more effluent that is produced, the more that will need to be stored

How can grass silage effluent be reduced?

Wilting is the most effective method – above 30% dry matter there should be almost no effluent.

What happens to fertiliser that is applied to grass?

Fertiliser nitrogen (N) is usually supplied as nitrate-N or ammonium-N. The latter is converted rapidly to nitrate-N in the soil, and this is the form of N that the plant takes up and uses to transport nitrogen around the plant.

In order to use this to make proteins, it must first be converted back to ammonia. This then combines with organic acid-based molecules to form amino acids, the building blocks of proteins.

Therefore at any one time nitrogen is present in plants in a number of forms. Shortly after fertiliser application it will mainly be as nitrate-N but over time this will change to protein-N. As the plant grows and its biomass increases, the total N concentration in the plant will reduce.

How to avoid or minimise slurry or fertiliser contamination in grass silage?

Slurry and FYM are heavily laden with undesirable bacteria which can survive on grass for many months. These include:

Enterobacteria:

- Compete for sugars required for fermentation

- Can produce toxins

Clostridia

- Can produce a secondary butyric fermentation

- Spores in milk can result in some cheeses blowing

If slurry is being spread, it needs to be applied to the soil, rather than the leaf, because of the damaging effects that slurry bacteria can cause to the fermentation and the other effects they can have (see above). Ideally, slurry should be injected. If not, then it should be applied with a trailing shoe.

Slurry also needs to be tested. Ideally, at least 10 weeks should be allowed between applying slurry and taking first-cut.

Preferably, only bagged fertiliser should be applied between cuts, as the risk of contaminating the grass leaf with slurry is too high. In practice, this may not always be possible. If applying slurry between cuts, reduce the application and make sure the slurry is of very low dry matter – about 2%. Again, ideally inject the slurry.

Caption: Ideally, at least 10 weeks should be allowed between applying slurry and taking first-cut, because of the damaging effects that slurry bacteria can have on the fermentation