Good silage starts in the field but finishes in the clamp

08 March 2021

Fermentation

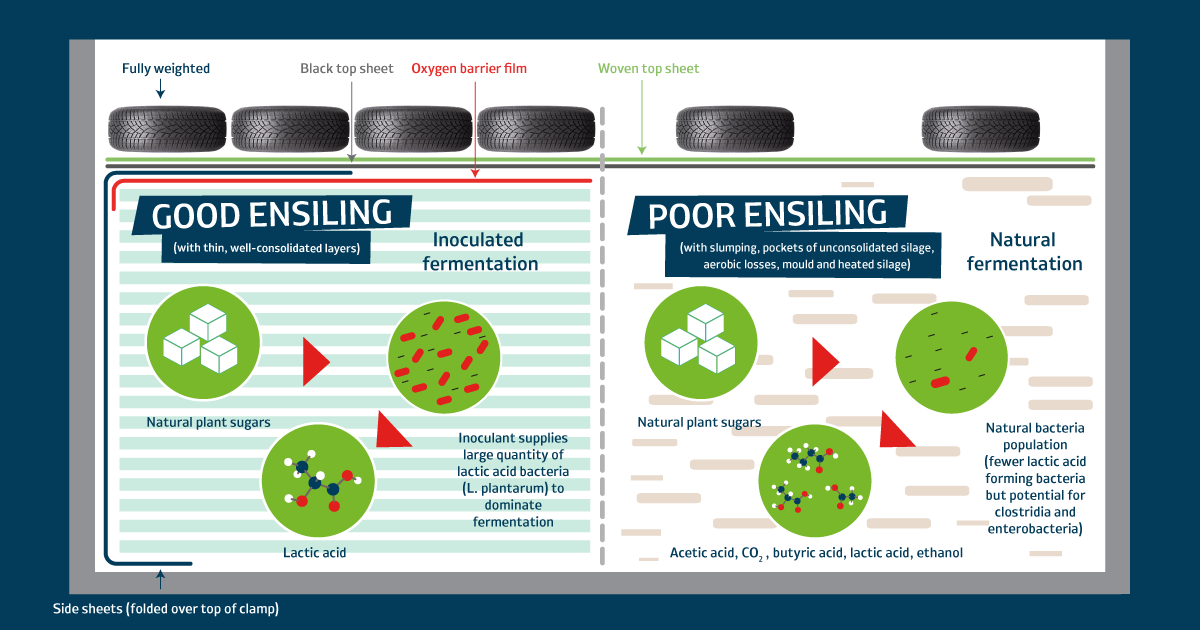

Fermentation relies on bacteria utilising sugars in the grass, but depending on the species of bacteria carrying out the process, the end products will differ.

This is according to Dr Mark Leggett, a silage scientist with Volac, who highlights the importance of the presence of the right bacteria in the fermentation process.__100_original.jpg?1615201401)

“To maximise the protein and energy content of silage, the fermentation should rapidly produce lactic acid as the principal end product. The beneficial bacteria, Lactiplantibacillus plantarum, facilitates this lactic acid fermentation.

“When lactic acid is formed during fermentation, it should quickly bring the pH down to between 3.8 and 4.5. This fall in pH prevents the growth of undesirable bacteria, limiting energy losses from the silage so the grower is preserving as much goodness from the grass he has grown as possible.”

‘Bad’ bacteria

Dr Leggett says the natural microbial population found on grass is an unknown and while some of the right bacteria for good fermentation are likely to be present, it is highly likely there will be populations of the ‘bad’ groups of bacteria.

“Clostridia and enterobacteria will ferment the sugars in the grass, but instead of forming only lactic acid, other compounds will be produced from the process such as acetic acid, butyric acid and ethanol. As a consequence, the pH will not fall as quickly as when lactic acid is the dominant end product.

“This is also a far less efficient fermentation process as it leads to losses of dry matter when carbon dioxide is formed and when protein breaks down to form ammonia. The ammonia and butyric acid causes the silage to smell unpleasant and forage intakes can reduce as a consequence.

“These undesirable bacteria are favoured by the slightly higher pH they create and so they thrive. Using an inoculant which contains a high dosage of L. plantarum ensures the right bacteria are present from the start of the fermentation process, so lactic acid is formed and there is a rapid drop in pH,” Dr Leggett says. Achieving the correct fermentation will ensure as much of the nutritional value of the grass is preserved in the silage, but then it is important to minimise further losses once the clamp is opened.

Aerobic stability

The aerobic stability of the silage is paramount if it is not to heat up and spoil once the clamp face is exposed to air. Dr Leggett says as soon as oxygen reaches the silage it activates the yeasts which can naturally occur on the silage and they cause the spoilage.

Good clamp management is essential in controlling aerobic stability, but faced with continual trouble with aerobic stability, Dr Leggett advocates the application of inoculants containing the bacteria, Lactobacillus buchneri to the silage because it ferments the sugars to produce both lactic and acetic acids.

“Although this process is not as efficient as when lactic acid alone is produced, it will inhibit the activity of the yeasts, thereby increasing the aerobic stability of the silage once the clamp is open.

Dr Leggett emphasises the difficulty in measuring the likely dry matter losses which occur either due to poor fermentation or spoilage.

“Estimates vary but dry matter losses are commonly around 10% of the total clamp dry matter but can be much higher.

“Given the amount of effort which goes into growing and harvesting grass, choosing the right inoculant to encourage a rapid lactic acid fermentation, or to promote aerobic stability when necessary, is a very wise investment.”

What do inoculants do?

Ecosyl contains MTD/1 and this is a unique, high performance strain of L. plantarum. It is applied at a million colony forming units per gram of forage, meaning it will quickly dominate the other less desirable bacteria. As a result, using Ecosyl 100 will enable the

L. plantarum bacteria to:

- Make better use of available sugars

- Preserve more nitrogen as true protein

- Reduce fermentation dry matter losses

- Minimise undesirable microbial activity

Alternatively, as well as containing MTD/1, the additive Ecocool also contains PJB/1 which is a unique strain of L. buchneri proven on a range of forage crops to inhibit the activities of the yeasts and moulds which cause aerobic spoilage of silages, with the following benefits:

- Less heating

- Lower DM losses

- Less physical waste

- Less risk of mycotoxins