What is aerobic spoilage?

What is aerobic spoilage?

_copy_original.jpg?1521897389)

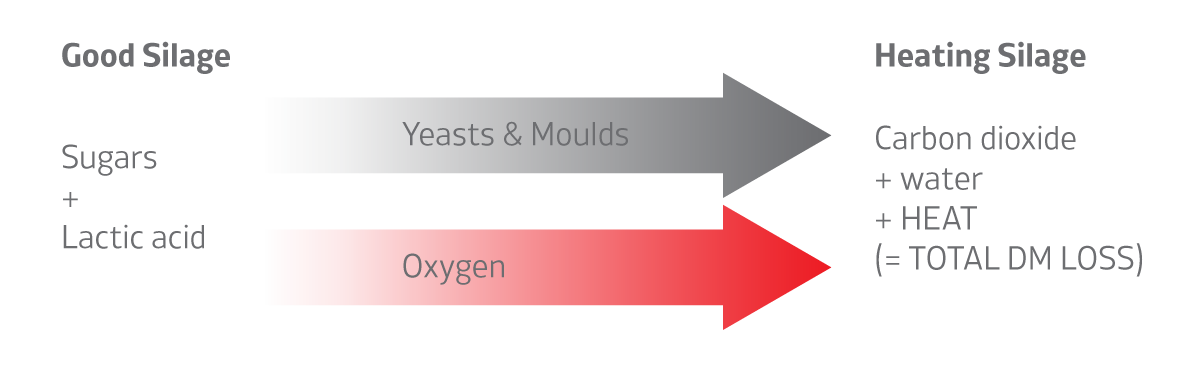

This is often wrongly referred to as secondary fermentation but it is not part of the fermentation process as it only occurs in the presence of air and fermentation, by definition, occurs only in the absence of air. It is initiated mainly by yeasts which can grow using a variety of different substances particularly residual sugars and lactic acid. They convert these to carbon dioxide and water and, in the process producing a significant amount of heat and high DM losses. After the initial yeast activity, moulds join in. They are able to grow on a wider range of substances so spoilage accelerates. Such silages will also have reduced palatability.

What are the major influences on aerobic spoilage?

- Exposure to air (most important)

– crop DM

– speed of filling

– compaction

– effective sealing

– feedout rate and technique - Fermentation

- Ambient temperature

What types of silage are most susceptible to aerobic spoilage?

- High dry matter silages

- Silages with high residual sugars

- Silages fed in warm weather

- Aerated silages, eg mixed in TMR

- Silages with high numbers of lactate assimilating yeasts at opening

How can I minimise aerobic spoilage?

- Narrow clamp face

- Shorter chopping for high DM silages to ensure good compaction

- Good compaction to minimise trapped air

- Good sealing and weighting of clamps

- Ensure no damage to sheeting or bale wrap

- Fast feedout (15 cm/d winter; 30 cm/d summer)

- Twice daily feeding in hot weather

- Keep clamp face tidy and tight (block cutter/shear grab)

- Keep the sheet off the open clamp face

- Use an effective additive