Can making silage with an additive improve animal performance?

Not all additives are proven to improve animal performance. Ecosyl, however, has a huge amount of proof behind it.

As well as improving grass silage digestibility, across a range of forages and dry matters, MTD/1 (the bacterial strain in Ecosyl) has also been shown to improve milk yield by an average of an extra 1.2 litres per cow per day across 15 independent dairy trials, compared with feeding untreated silage.

Across 19 independent beef trials, MTD/1 has also consistently produced more beef – with liveweight gain in growing cattle increased by more than 11% in 10 trials, and carcass gain in fattening cattle increased by more than 9% in 9 trials.

Can an additive stop grass silage heating?

Unfortunately, no matter how efficient the fermentation, it cannot inhibit all microorganisms. Certain yeasts can survive in low pH conditions and feed on lactic acid when exposed to air. This reduces the silage’s dry matter (DM) and energy through the production of carbon dioxide and release of heat in the process of aerobic spoilage (heating).

This is a particular problem in higher % dry matter forages that are more difficult to consolidate. As the yeasts use up lactic acid, the pH rises again allowing other undesirable fungi to grow. Other consequences include reduced palatability and potentially production of mycotoxins.

Farmers have little control over the numbers of yeasts on the crop, but what is possible is to limit their growth on the silage. As well as practices such as consolidating and sealing clamps well, a dual-acting inoculant can help.

The dual-acting inoculant Ecocool contains a tailored dose of the same proven Lactiplantibacillus plantarum MTD/1 found in Ecosyl for fermentation, but blended with a second bacterial strain, Lactobacillus buchneri PJB/1. This second strain generates acetic acid, which has anti-yeast properties. Ecocool has been shown to both reduce yeast levels and keep silage cool and stable for more than 10 days on exposure to air.

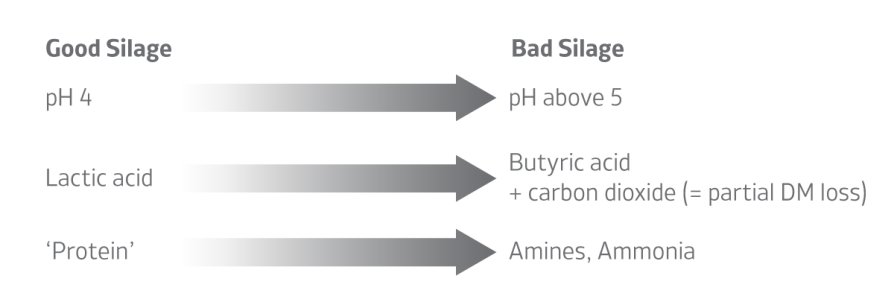

What is clostridial secondary fermentation?

This occurs before the silo is opened in the absence of air and when a stable pH value is not achieved initially, often because of insufficient sugars or contamination from soil or slurry.

A particular group of undesirable bacteria (clostridia) converts the lactic acid already produced into butyric acid, a weaker acid, so the pH increases. Some clostridia also break down amino acids, resulting in high ammonia levels and some extremely unpleasant products, e.g. putrescine and cadaverine. Dry matter losses will be high and the final silage is unpalatable and has a low feed value.

The major influences on clostridial secondary fermentation:

- The dry matter/sugar contents of the crop ensiled

- Initial clamp management

- Contamination (soil/slurry)

- Use of an effective additive

Is a high lactic acid content in silage a problem?

Lactic acid per se is not a problem. However, silages with particularly high lactic acid levels are generally wetter silages that may have undergone an extended fermentation leading to high levels of total acids in the silage and a high buffering capacity. It is the buffering capacity and the total acid content that should be considered, not the lactic acid content alone. Silages with a higher proportion of lactic acid in the total acids tend to have a lower buffering capacity.

Recognising the type of fermentation that has occurred and balancing the diet properly will prevent any problems with these silages.

Should an additive be used on low sugar grass?

Grass can often be low in sugars and/or have low numbers of beneficial lactic acid-producing bacteria present on it. Use of a proven additive helps to counteract these to ensure a successful fermentation.

If sugar is limiting, a stable pH value may never be reached. This can allow other very undesirable bacteria, e.g. clostridia, to take control, changing a poor fermentation into a very bad fermentation with a much-reduced nutrient value and high losses.

Should an additive be used on low % dry matter (DM) grass?

With low dry matter (< 20%DM) grass an additive is usually considered essential, especially if harvesting conditions are not ideal and/or the grass has a high clover content.

This is because very wet grass silage stabilises at a lower pH and the acid produced is diluted so more acid is needed. This means more sugar is also needed and a minimum of 3% (fresh basis) used to be recommended. However, if an effective additive is applied it may be possible to get away with significantly less sugar as the sugars are used more efficiently.

Is an additive needed for high dry matter (DM) grass silage?

With high %DM grass the fermentation is slower and the silage will stabilise at a higher pH. The slow fermentation allows more time for undesirable microorganisms to be active as well as increasing the breakdown of true protein. A bacterial additive speeds up the process as well as making it more efficient with lower DM losses.

High %DM silages are also at higher risk of aerobic spoilage (heating) at feed-out, with potentially high losses and the risk of mycotoxins. Good management is therefore essential and additives are also available to help reduce aerobic spoilage, although an additive is not a substitute for good management.

How can I trust a silage additive?

Two ways. Ask to see scientific proof that it works. And secondly, look at the quality of the product and how it is made.

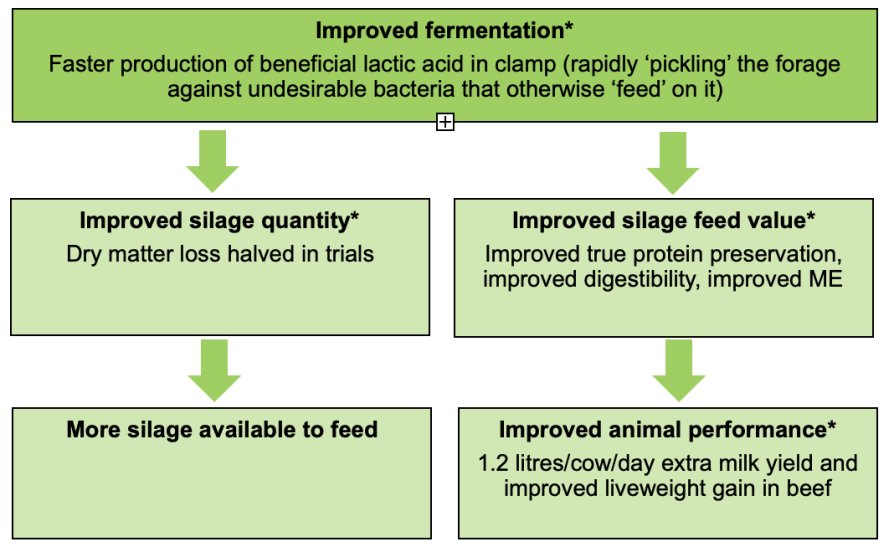

With Lactiplantibacillus plantarum MTD/1, the bacterium used in Ecosyl, there is a huge amount of research to pinpoint the logical sequence of benefits the treatment brings – from application right through to animal performance (see graphic below).

In addition, Ecosyl products are backed by over 30 years’ experience in the manufacture of silage inoculants. Continuous research in fermentation, preservation and product formulation has resulted in product improvements.

During its manufacture, the continuous culture method used means the bacteria it contains are fed nutrients continuously and harvested continuously, which enables them to be harvested while they are actively growing so they are in peak condition. This means they are ready to start working as soon as applied.

Special ingredients protect the cells during freeze drying and aid rapid recovery on re-hydration. Combined with MTD/1's inherent characteristics, the result is a highly stable bacterium which remains active even when stored at ambient temperature.

Finally, the treatment is expertly formulated with special, fully traceable ingredients added. This provides Ecosyl with a long shelf life so that any unused product can be easily stored, while allowing rapid re-activation of the bacteria on contact with moisture and a long tank mix life so temporary delays during harvest are not a problem.

MTD/1 (in Ecosyl) – tested extensively

- More than 200 fermentation trials

- Intake/digestibility/ME feeding trials

- Animal performance trials

Sequential benefits of Lactiplantibacillus plantarum MTD/1 (Ecosyl) treatment based on research

* Compared with no additive used

* Compared with no additive used

Can silage additive use be made easier or quicker?

A technique that can make using Ecosyl (and sister additive, Ecocool) even easier is to apply it via the ultra-low volume (ULV) application method. Compared with traditional application of applying in 1-2 litres of water per tonne of forage, in the ULV method Ecosyl and Ecocool can be applied in just 20 ml of water per tonne. (Note – volumes less than 1 litre per tonne are only recommended for self-propelled harvesters to allow for even distribution of the additive throughout the crop.)

This not only reduces the downtime needed for fill-ups, it also massively reduces the volume of water that needs to be lugged out to the harvester in the field. This can be used to free up labour, for example to drive an extra machine to consolidate the clamp.