Waste not want not at silage time

29 May 2020

In bad times why risk making anything but the best possible silage with the most proven additive?

Using an additive improves silage fermentation and quality, but also pay attention to how your fill that silage clamp.

Silage is produced when beneficial bacteria ferment some of the sugars in grass to lactic acid. This ‘pickles’ the grass – preventing the growth of spoilage micro-organisms – and preserves nutrients. An efficient fermentation requires air-free conditions within the clamp. Additives also play a key role in reducing DM losses.

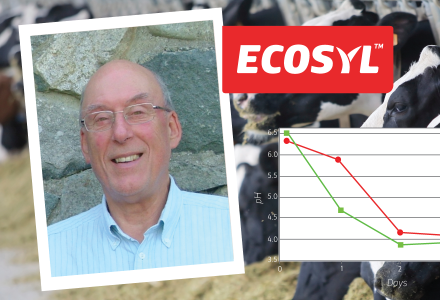

A quality bacterial additive can improve ME and D value to boost milk yield by an average of 1.2L/cow/day, in the case of Ecosyl containing Lactiplantibacillus plantarum MTD/1.

Don't leave preservation to chance

Do not leave preservation to chance as you do not know if bacteria populations on grass are sufficient for an effective fermentation. When used correctly, a quality additive will supply one million ‘good’ bacteria per gram of forage thus offering assurance of a good fermentation.

15 independent trials, using the MTD/1 strain of Lactiplantibacillus plantarum in Ecosyl, have shown that dry matter (DM) recovery was boosted by 3.7% when compared to non-treated silage. And if 1,000t of DM silage were clamped that would equate to an extra 37t back at feed-out.

Given the increase in energy content, digestibility and DM intakes, the use of treated silage also leads to better animal performance. In trials live-weight gain achieved by finishing beef animals was 19% higher on treated silage compared to untreated silage.

Find out more about the features and benefits of using Ecosyl.

Consolidating the clamp

However some of us still do not roll and consolidate clamps properly thus leading to reduced quality the following winter.

Failing to consolidate the clamp properly can lead to reduced fermentation, more waste and increased aerobic instability problems at feed-out.

Therefore, squeezing as much air as possible and achieving the correct clamp density is vitally important. Removing these air pockets is necessary as the fermentation and preservation process needs an oxygen-free environment.

Often silage isn’t consolidated enough simply because trailers are arriving at the clamp too quickly and grass is not spread properly. A case of more speed, but less quality feed next winter!

Top tips for consolidation:

- You can only really efficiently consolidate the top 15cm. So layers should be even and no greater than this depth, before being rolled and the process repeated with the next layer

- For a grass silage at 30% DM, aim for a target silage density of 250kg of DM/m³ or 750kg/m³ in fresh-weight terms. Also, avoid over-filling the clamp as once clamps are filled above the wall level the density drops.

- Once the clamp has been well rolled, sealing the clamp will stop oxygen from entering the pit. It is advisable to use side sheets and to leave a good overlap with the top sheet of preferably 1.5m.

- These side sheets should be folded in once the pit is full, an oxygen barrier film placed on top and then a top sheet fitted. Also ensure that as much weight is placed on top of the clamp as possible. This weight maintains better density in the weakest part of the clamp – the top.

Take care at feedout

Looking ahead care will be needed at feedout so leave at least half a metre of extra silage sheet at the front of the clamp.

This sheet should be weighed down to prevent any carbon dioxide from exiting the clamp or any oxygen from entering. If carbon dioxide is allowed to seep out of the bottom of the clamp, because it is heavier than air, it creates a vacuum, which sucks oxygen in.