The low-down on ultra-low volume additive application

05 May 2021

Ultra-low volume (ULV) silage additive application offers great potential for farmers and contractors, compared with applying additives in conventional water volumes. So how could you benefit from it?

What is ULV?

As well as being suitable for applying in conventional water volumes, such as 1 or 2 litres per tonne of forage treated, certain additives can be applied in ‘ultra-low’ water volumes.

For example in 20 ml of water per tonne.

Which means up to 100 times less water needs to be handled, fetched and carried.

How does ULV work?

As an example, a standard 2-litre bottle of Ecosyl contains enough freeze-dried beneficial bacteria to preserve 100 tonnes of forage.

With conventional application, the contents of the bottle have to be diluted* with 100 litres of water if applying at a volume of 1 litre per tonne of forage, or with 200 litres of water if applying at a volume of 2 litres per tonne.

With ULV, on the other hand, the Ecosyl bottle is simply mixed* with 2 litres of water (there’s a handy 2-litre mark on the bottle), then poured directly into the specially-designed ULV applicator tank. This allows an application volume of just 20 ml per tonne of forage.

In each case, the same 2-litre bottle of Ecosyl is enough to treat 100 tonnes of forage and the same quantity of beneficial bacteria is being applied per tonne. It’s just that with ULV it is being delivered onto the forage using much less water.

* Whichever method is used, the bottle must first be approximately three-quarters filled with water and shaken to allow enough room for a good agitation before the final dilution is carried out

Illustration

Conventional application*

2-litre Ecosyl bottle:

- Mixed into 100 litres of water à Application volume of 1 litre/tonne

- Mixed into 200 litres of water à Application volume of 2 litres/tonne

ULV application*

2-litre Ecosyl bottle:

- Diluted to 2-litre level with water à Application volume of 20 ml/tonne

So what are the potential benefits of ULV?

Utilising ULV application potentially offers direct and indirect benefits. It can help to streamline the whole harvesting operation.

1. Time savings

Carting and mixing large volumes of water for conventional application can be pretty much a full-time job on the day of harvest with large harvesters – either for the contractor, the farmer or farm staff. By making the mixing process much quicker, ULV releases this time and labour – for example so that it can be spent on other more productive tasks.

Time savings from less carting can be particularly significant if the farm’s silage fields are located at a distance from the farmyard. And there can be other gains – such as less waiting around for tractor / rake combinations in the field while the additive tank is refilled.

2. Less effort

Using ULV is much less cumbersome than lugging about big barrels of water or lifting pumps in and out of barrels. Bottles for ULV application can be mixed virtually anywhere, and the day’s additive requirement is easily carried in the harvester or carried out to the field by a tractor returning from the clamp.

Any Ecosyl that has been mixed for ULV application is also easy to put back into its bottles if harvest is interrupted due to rain or breakdowns. In its bottle, diluted Ecosyl can be stored if refrigerated for up to 10 days. That compares with 1-2 days’ shelf life for a mixed barrel of the additive stored at ambient temperature.

3. Potential financial gains

Less stoppage time refilling the additive tank also means more hectares can be harvested per day – which increases the chance of ensiling the crop within available weather windows in catchy weather, or in optimum condition, such as not over-wilted. Diverting labour saved from mixing large quantities of water to other more productive tasks (such consolidating the clamp better with an extra tractor) can also help to produce better silage by reducing waste.

What’s more, the ease of mixing an extra additive batch with ULV can cut the temptation to leave the last few loads on top of the clamp untreated if the tank is running dry near the end of the day. This is important because the top of the clamp is most vulnerable to heating and spoilage. There can even be savings from not having to buy or maintain water bowsers or lay on water supplies to silage fields.

Ultimately, having a simpler and less hectic harvest workload could also lead to less stress and reduce the chance of costly mistakes.

Setting up for ULV

This technology has been in use for around 20 years. Although all self-propelled forage harvesters should be suitable for ULV application, certain types of harvesters – such as forage wagons and trailed harvesters – may not be. So check this. Other than that, you simply need to install the ULV applicator, and choose the appropriate additive.

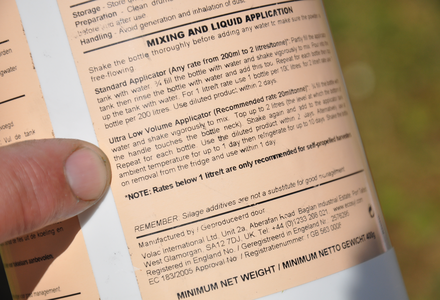

Be aware, however, that not every additive can be applied via ULV. If it doesn’t say suitable for ULV on the label, it may not be. DO NOT assume that it is. It is vital to check.

Ecosyl products that are suitable for ULV application are Ecosyl 100 for clamped grass and legumes, and Ecocool for forages at risk of aerobic spoilage (heating), such as maize, wholecrop cereals, and higher dry matter grass silage.

Head over to our Products' area to find out more about the Ecosyl range of silage additives

The Ecosyler ULV applicator has also been engineered for precise delivery of product. It achieves an even distribution by atomising the ULV liquid in the forage harvester’s airflow.

Find out more about using Ecosyler

Why aren’t all additives suitable for ULV application?

Because ULV application is in millilitres of water per tonne rather than litres, it is crucial that the additive still works as it’s supposed to at these low volumes. Beneficial bacteria in the additive must remain viable in such a small quantity of water. They must also remain in suspension without settling out. Otherwise they will settle to the bottom and be applied too heavily at the start and possibly only cloudy water applied at the end. Similarly, the product must maintain an even application of the forage in the machine, and it must produce the same level of fermentation in the clamp. You can’t assume all additives have been formulated to these standards.

In the case of MTD/1 bacteria in Ecosyl, there has been a huge amount of research to check these areas: trials have shown no difference whether applied using ULV or conventionally. ULV maintained accurate, even application of the required number of beneficial bacteria per gram of forage, and there was no difference in the fermentation – with both application methods producing significantly better silage than the untreated with higher ME and true protein and reduced dry matter losses.

Find out more about the benefits of using Ecosyl.

Ready to start using Ecosyl? Head over to our online order form today.