Better aerobic stability

Forage that is undergoing aerobic spoilage (heating and moulding) will result in potentially extremely high DM losses as well as have a significant impact on animal performance due to reduced palatability, lower feed value and the possibility of mycotoxins production. Animal health and fertility may also be affected.

Honig (1990) determined that for a silage of 30% DM, every 1°C increase in temperature above ambient would result in a 0.23% per day loss in dry matter. This can soon mount up for a silage that is heating badly, especially if the feedout rate is slow (Table 1).

Table 1. DM loss (%)

| Days heating | |||

| Increase in temperature | 3 days | 5 days | 7 days |

| 5 | 3% | 5% | 7% |

| 10 | 6% | 10% | 14% |

| 15 | 9% | 15% | 21% |

Source: Honig 1990

Example

- 0.23% DM per day for every 1°C increase in temperature

- 4 days: 20°C increase

- 18.4% DM loss

- With 30% DM maize @ £132 per tonne DM (Kingshay, 2015) = £24/t DM ensiled

- 1000 tonne clamp (300 tonne DM) = £7,000 loss in feed value

Consequences

High DM losses

- Losses are directly proportional to the amount of heat produced

- Less to feed

- Increases the silage production cost

- Decreases in palatability and nutritional value

- Potential production of mycotoxins

- Severe implications for animal production, health & fertility

Susceptible silages

- High DM

- High residual sugars

- Fed in warm weather

- Aerated in TMR

Improved aerobic stability with proven Ecosyl additives

The DA and Ecocool ranges of silage additives have both been proven to improve the aerobic stability of silages.

DA range

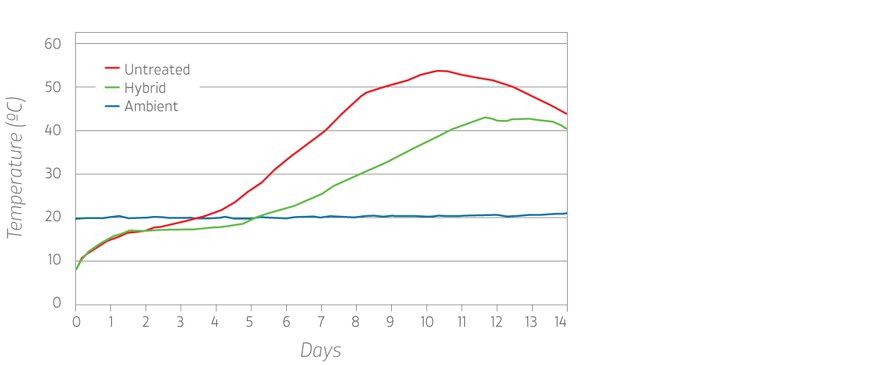

A trial with 38% DM grass at AFBI, Hillsborough, showed how DA Ecostable can reduce both the rate and extent of aerobic spoilage in high DM silages.

‘It is evident that the additive significantly improved the aerobic stability of the silage.’

‘It is evident that the additive significantly improved the aerobic stability of the silage.’

Dr D Patterson AFBI, Hillsborough (2000)

Ecocool

Ecocool

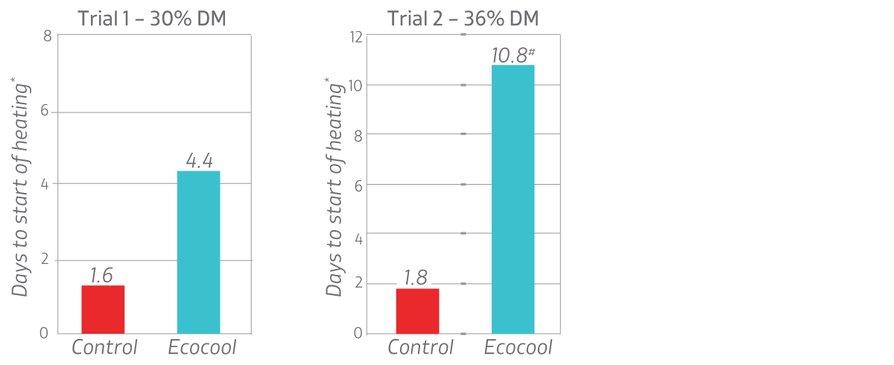

In two maize trials with Prof. Limin Kung at the University of Delaware, Ecocool treated silages were significantly more stable than the untreated controls.